Adiabatic Compressed Air Energy Storage

Large-scale, cost-effective energy storage is generally considered to be one of the key missing pieces of the puzzle for a sustainable energy future. Compressed Air Energy Storage (CAES) is a form of energy storage with signifcant potential for global expansion which is entirely composed of mechanical and thermal components. There are two commercial grid-scale CAES plants currently in existence; Huntorf, Germany (commissioned in 1978 -- see Figure 1) and McIntosh, Alabama (commissioned in 1991) which represent about 440 MW of power and in excess of 3 GWh of energy storage. These two plants, however, are not purely electricity storage, as they also use natural gas, running a process very similar to an open cycle gas turbine except that the air is pre-compressed, rather than operating the compressor and the turbine simultaneously.

To overcome the need for fossil fuel, variations of the CAES concept which do not use natural gas have been proposed. In Adiabatic CAES (ACAES), heat generated during the compression is stored and then returned to the air prior to expansion, replacing the use of fossil fuel. An illustration of ACAES operation is shown in the Figure 2 below. However so far - despite much promising research - a successful prototype ACAES plant has yet to be demonstrated. Our research in the ESES lab aims to bring ACAES from concept to reality. We perform thermodynamic analysis, simulation, modelling and conduct experiments designed to improve the performance of these systems. Our work spans from designing individual system components (for example, heat exchangers in ACAES systems) to whole system design, optimisation and integration of ACAES into wider energy systems.

Previous work from the group has investigated the potential for using packed bed heat exchangers in ACAES. Packed beds are particularly appealing in ACAES systems due to the exceptionally high heat transfer rates available, simple construction required and low-cost thermal storage materials (i.e. crushed rocks or ceramics). Our paper describing this analysis has been published in the journal Applied Energy. A video of the thermal simulation is shown below.

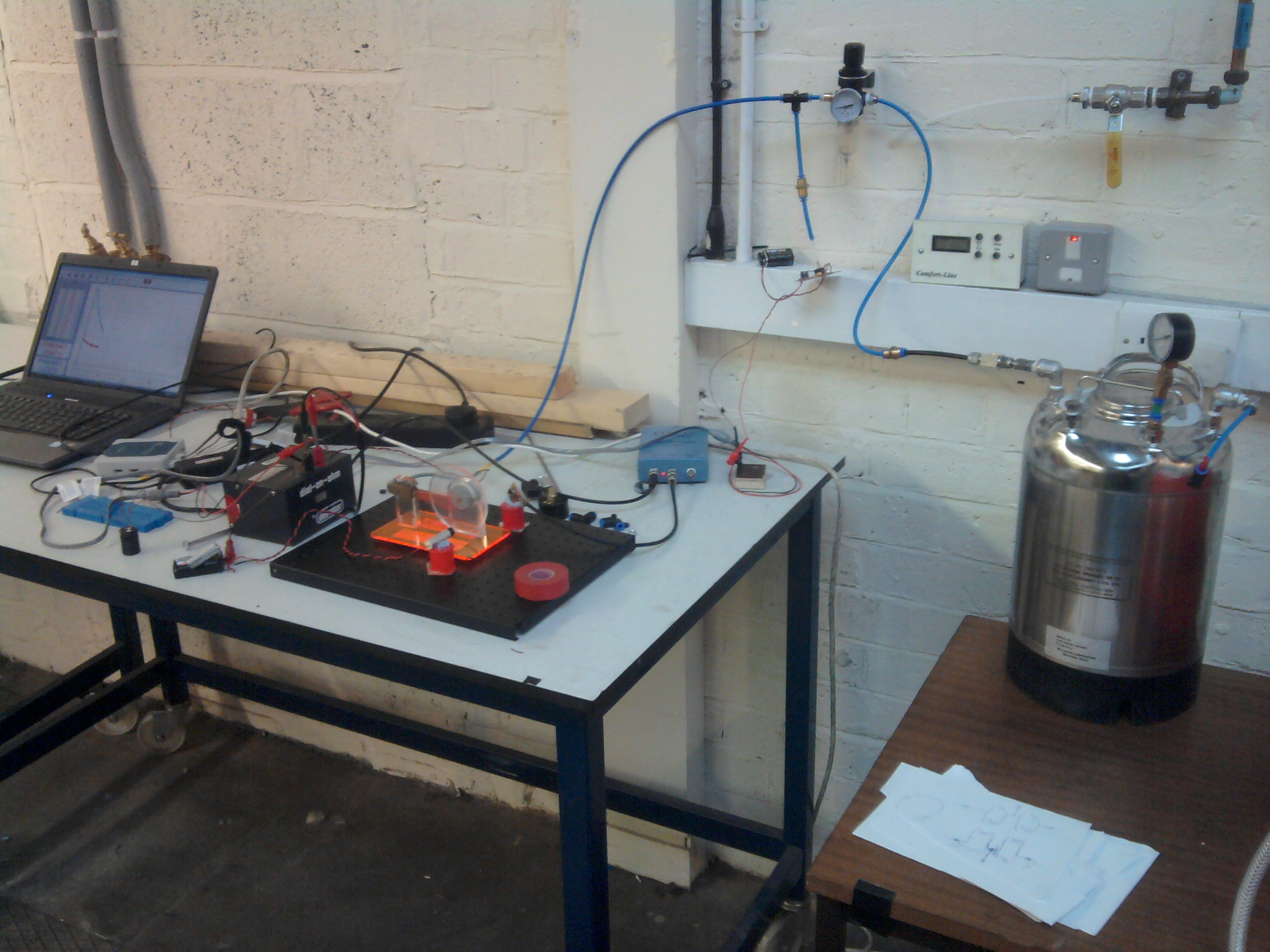

Figure 3 illustrates a previous experimental setup for testing CAES discharge on a micro-level. We used a small-scale positive displacement expander and measure the power at the shaft. Recording over the tital discharge we can get the total work output from the air tank discharge and infer the system efficiency.

Isobaric CAES

While the concept of ACAES is well-established by numerous publications – there are a range of engineering challenges which are yet to be overcome. One significant problem with current design of ACAES systems is transient storage pressures which cause inefficient turbomachinery operation and introduce other losses. Our research seeks to address this challenge by developing a novel method of isobaric air storage. We are exploiting the high compressibility of CO2 in the two-phase liquid-vapour region to create a ‘pressure buffer’, allowing the pressure change during charge and discharge to be minimised, thus improving performance. We are also interested in other methods of isobaric storage, including hydraulic compensation and flexible boundaries.